In the world of marine conservation, the search for effective materials to aid restoration is a never-ending exploration. For oyster reefs specifically, a suitable substrate is the key in achieving reef revitalisation. Among the many materials, clay stands out as a tested solution which has led us at Oyster Heaven to use it as the preferred material to kick start large-scale oyster reefs.

In historic practices, oyster farmers often used clay roof tiles to catch oyster larvae during swarming season. Roof tiles were easily available and low in costs. Ahead of spawning, the roof tiles were placed in the water where they provided a surface for larvae settlement. This historical practice not only underscored clay’s effectiveness to attract oysters but also its accessibility and cost-efficiency.

Fast forward to contemporary conservation efforts, and clay remains an often used material in restoration. For oyster reef regeneration, it is commonly considered for a substrate, which is essential for revitalising oyster reefs. In the wild, oysters settle on hard substrates, preferably other shells; in the absence of those, restoration efforts work with alternatives, both organic and inorganic.

In a recent experiment, researchers compared substrates for oyster settlement. Materials including granite, mussel shells, concrete and roof tiles were assessed (Ter Hofstede et al., 2024). While the roof tiles in this study didn’t exhibit the highest settlement rates among these materials, clay tiles did show respectable rates of settlement. Similar findings have been reported in other studies, such as one conducted by Colsoul et al, who attributed clay’s effectiveness to its high silicate and calcium magnesium content, as well as its rough surfaces, resembling the composition of shells (2020).

Beyond effectiveness, clay’s sustainability, availability, and low environmental impact make it an appealing choice for restoration projects. Moreover, its non-toxic nature is compatible with delicate marine ecosystems—an important consideration in conservation.

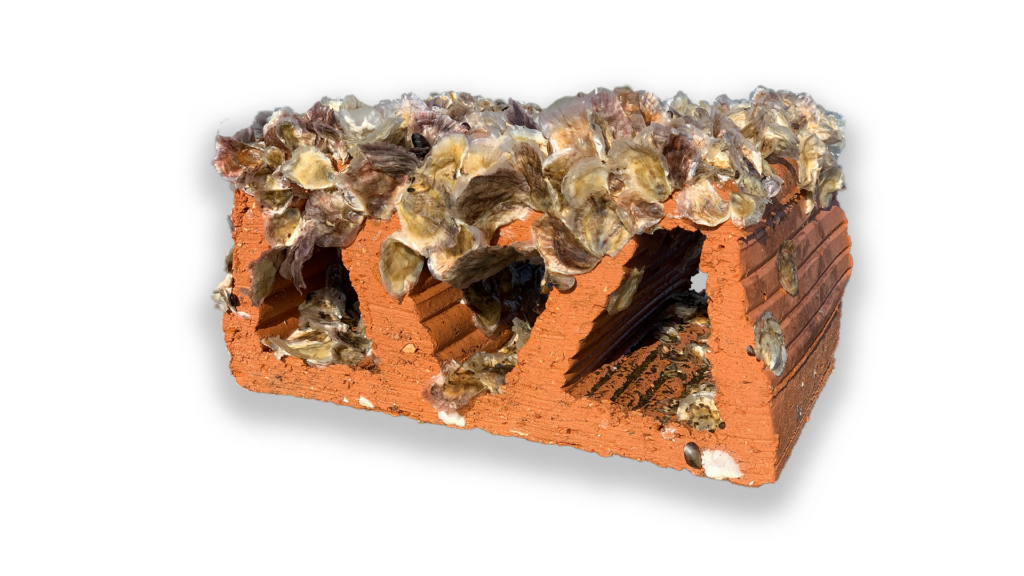

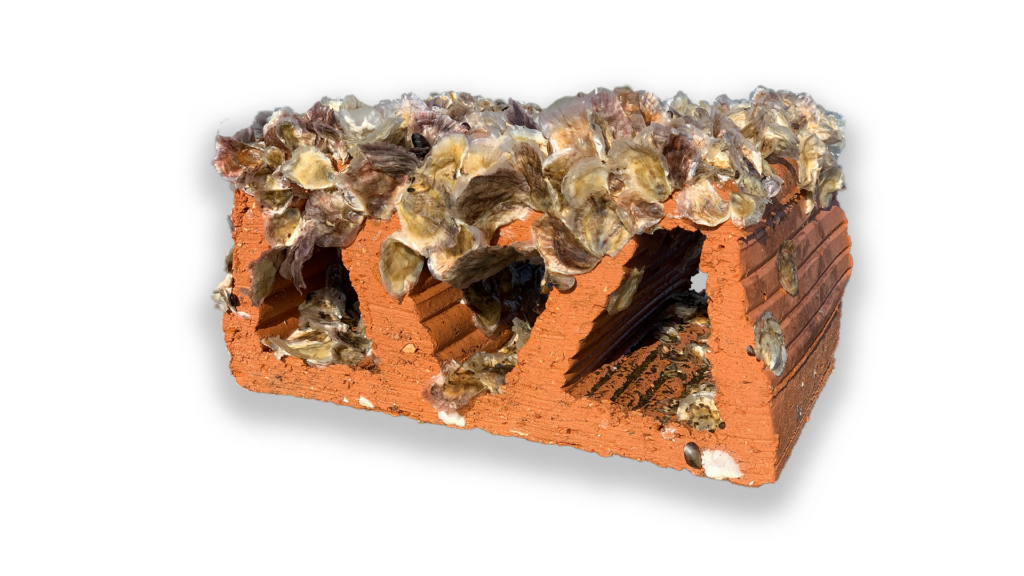

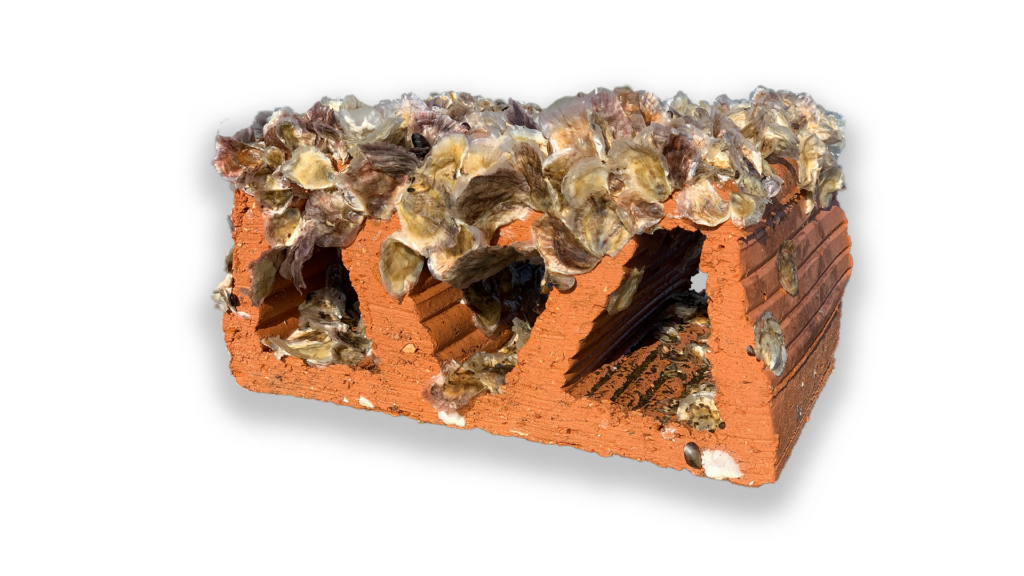

At Oyster Heaven, we’ve explored clay’s potential for reef structures. Recognising the need for a complex structure to mimic natural reefs, we leveraged clay’s adaptability to design three dimensional shapes. Through manufacturing, clay is moulded into the ideal substrate shape: our Mother Reefs, featuring wave-like contours, rough surfaces, and cavities—perfect for habitat creation.

One of clay’s biggest advantages lies in its stable and substantial supply, available almost everywhere. Drawing from its widespread application in construction, clay products can be mass-produced to meet the demands of restoration projects. By using generic equipment, as we’ve done at Wienerberger in The Netherlands, brick factories can produce large batches of clay substrate. This streamlined production process not only ensures scalability but also simplifies the handling of substrates during settlement and deployment—a critical factor in large-scale restoration efforts.

Building upon experience, researchers have found innovative strategies to kickstart reef ecosystems. Preparing substrate with pre-settled spat has emerged as a promising approach to accelerate reef formation. In many restoration projects, empty shells are used to settle oyster spats on. Our clay Mother Reef is charged with flat oyster spat prior to deployment, jumpstarting the colonisation process and giving the baby oysters a head start in the wild. This proactive approach not only enhances reef establishment but also underscores clay’s compatibility with biological processes.

As we tackle ocean conservation challenges, clay is just the beginning of a solution that has the potential to become even more eco-friendly as we continue our efforts.

Make a measurable difference for the ocean today.

You can now adopt a Mother Reef and help restore 100 oysters!